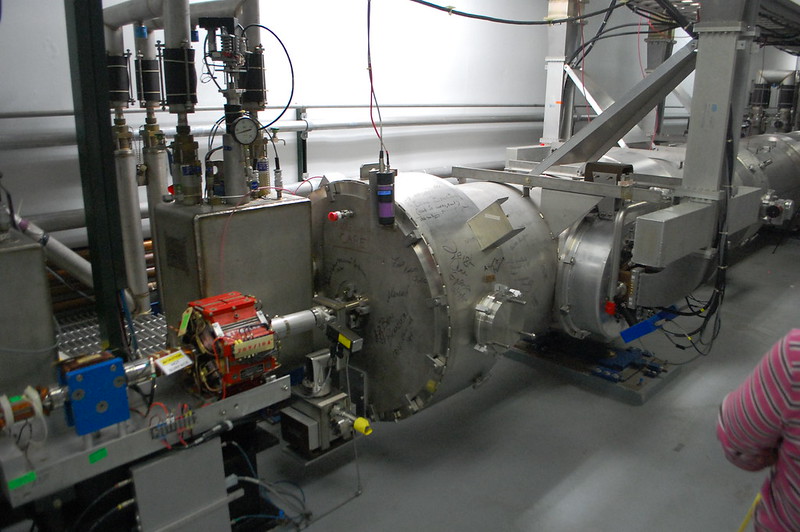

I drew this part up in 1997 while I was working at Jefferson Lab in Virginia. It’s a simple part with complicated requirements. For the Free Electron Laser we had to transfer very high voltage from the power supply to the electron gun. In order to do that the EE in charge wanted to use aluminum pipe as the center of the conduit. He also insisted on using a corona ring as the elbow for the conduit. This didn’t work out because it’s very difficult to make a welded pressure vessel from aluminum.

Here’s this part welded into the inner conduit. The issue with this part is that sharp corner around the outside end. This where I learned that when it comes to high voltages, curves are your friends. Otherwise BZZZZTT!!! Still in all it was a fun project.